As the market for coordinate measuring machines grows, you will discover that there are many different places you can go to buy one, from auction houses to used dealers to independent retailers to the OEM. However, not all suppliers can offer the same services or support and you will quickly realize that owning a coordinate measuring machine is not as simple as buying one. In addition to regular recalibrations and maintenance, they have to be recertified each year, the technology (especially software) is always changing, and your own inspection needs are constantly evolving as your clients expect better accuracy and you introduce new components to your line.

If you are in the market for quality CMM equipment, you can simplify the process by going to an independent supplier who will not only take care of your ancillary metrology needs, but who will also make sure that you’re getting the best fit for your shop. Below are some of the ways that an independent supplier can help your purchasing process and ensure that you get the results you expect from your inspection department.

#1 The Right Equipment:

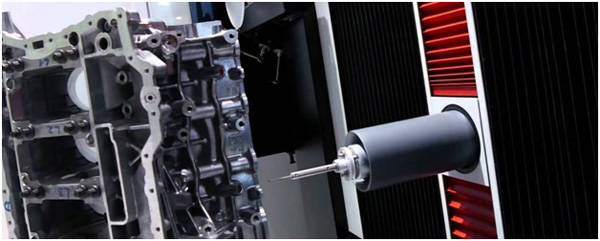

There are so many different types of coordinate measuring machines available on the market today and the choice you make should be guided by the kinds of components you need to measure. In addition to choosing between bridge-style, gantry, horizontal, vertical, and shop-floor ready machines, you also have options such as portable arms, laser scanners, and vision systems, not to mention choosing a probing system. Add in specifications such as accuracy, repeatability, range, and throughput, and it can be a lot to take in; a reputable independent supplier will help you through the process, whether you already understand your metrology needs inside and out or you’re new to purchasing this kind of equipment.

#2 Assessment:

One of the marks of a good independent supplier is their willingness to make sure that you truly get the right piece of equipment that will fit not just the tasks but also the space. As a member of the MDNA, metrology supplier Canadian Measurement Metrology Inc. (CMM) makes it its business to improve inspection processes across North America. They visit your shop and assess the space to check it against the machine’s footprint and how well it can be integrated into your line, as well as assessing air quality and electrical supply, all of which are essential to maintaining a coordinate measuring machine.

#3 Software and Training:

Finally, there’s also the software, which is where things can become very complicated as many OEMs offer their own software, while some shops choose to opt for a different package, such as the globally-popular PC-DMIS. Even within the PC-DMIS line, there are software packages for a range of different tasks and technologies, from PC-DMIS NC to CAD, Gear, Blade, Portable, and laser tracker. Your employees also need to learn how to use your software to operate machines and program parts routines. One unique solution offered by CMM is their PC-DMIS E-learning course, which allows you to train operators without sending them away from the shop for weeks.

Before you make a considerable investment in your inspections department, find a supplier who can help you every step of the away, even years after your initial purchase.