3D printing, also known as additive manufacturing, is a modern innovation that initially made waves for its ability to produce cheap and quick prototypes, replacement parts, customized prosthetics, denture components, and similar objects. Such items, while nonetheless vital and helpful, were considered relatively inconsequential in the scheme of large-scale manufacturing. However, these days, the potential of 3D printing is increasing in relevance and versatility, thanks to the significant improvement of the technology. Experts from various industries—from consumer products and electronics to automotive and aerospace—are all excited with the prospect of utilizing 3D printing to change traditional manufacturing processes and systems.

Below you will find how 3d printing can change manufacturing, let’s read the article below.

Must Read–

7 Excellent Tips to Choose Printer for Brochure Printing

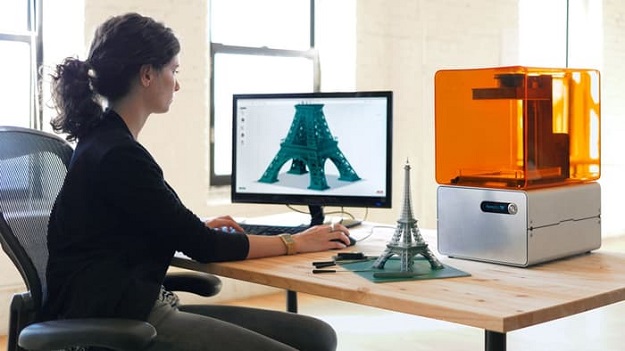

3D Printing: How the Technology Works

Basically, 3D printing is the process of creating a three-dimensional object using successive layers of material, usually plastic in filament form. The material is heated and passed through a nozzle in an extruder, to create or “print” the object. A vital part of the 3D printing system is motion control, which is responsible for guiding the movable parts to accurately produce the object.

The Cartesian model utilizes an XYZ linear stage system where the overhanging structure with its motors can each move along the X, Y, and Z axes. This system is typically in a rectangular build area. Another type called Delta printers have three arms that join in the center, with the extruder suspended above the build area. It also utilizes Cartersian coordinates to guide movement, but instead of moving one stage on each axis, all three arms triangulate to move the extruder and nozzle.

Another part of the 3D printing system is the cooling fan, which is used to harden the molten plastic once it is extruded so that it holds its shape and form. Heat sink fans are also used to ensure that the plastic filament does not melt before it is extruded. Thermistors, on the other hand, regulate the temperature for melting the filament. Finally, gears, belts, leadscrews, and stepper motors also comprise the overall motion control system within a 3D printing device.

3D Printing’s Impact on Waste Reduction, Manufacturing Costs, and Customization

One of the biggest impacts that 3D printing technology may have on manufacturing is the potential elimination of waste and scrap material. In traditional processes, for instance, a part to be produced out of metal would be achieved through a “subtractive process,” wherein the material would be placed in a CAD system and the design would be cut out from the metal, resulting in excess waste material being discarded later on. 3D printing, being an additive process, would be able to achieve substantial cost savings on raw materials and scrap re-processing.

The traditional method of assembly line production would also be disrupted using a 3D printing system, which is more flexible and on-demand. Salespeople would be able to accept more orders and deliver in a timely fashion, without being restricted by production stages and timetables.

Most importantly, customized design can be achieved for customers more accurately and freely. Instead of template designs or pre-fabricated components, unique output can be produced as needed and when needed. This translates to more orders, increased sales, and wider margins of profitability for the manufacturing company.

3D Printing Solutions

There are still many skeptics who are not optimistic about the application of 3D printing technology in large-scale manufacturing, primarily in terms of speed, scalability, and reliability. However, as time goes on and the technology improves even further, 3D printing will slowly but surely gain a foothold in many industries. Right now, a global shoe manufacturer is already innovating a 3D process of manufacturing entire soles from liquid polymer.

In the field of construction, a start-up company based in Dubai has developed a 3D-printing crane that can churn out as much as 200 square meters of building concrete per day, potentially changing the way that infrastructure is built in a fast but sturdy manner.

Indeed, the world of manufacturing is entering a new phase of possibilities, thanks to the 3D printing technology. Only time will tell how successful it will be implemented in mass manufacturing and mass customization applications as more and more businesses take a chance on this innovation.