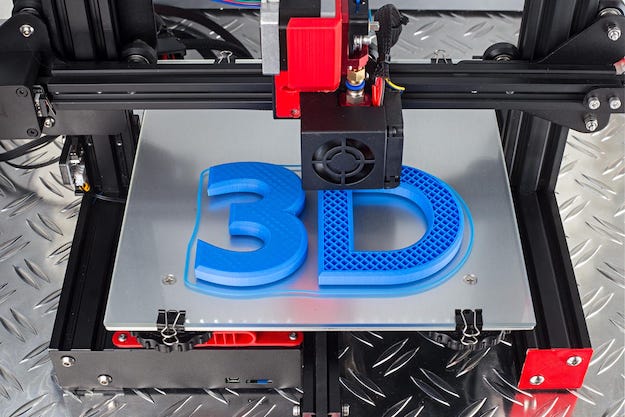

It’s no hidden secret that 3D printing is the future of manufacturing. If you don’t believe it, you only have to look at the development within the last few years.

But while most people are celebrating the future of 3D printing because everyone wants to own a 3D printer in their house, there’s another group that actually has much more to gain from its progress. And that is construction companies.

3D printing and 3D technology have become crucial aspects of construction technology. It has the power to supercharge the speed of construction site broadband, which is essential for keeping up with rapid development cycles.

With superfast construction site broadband on construction sites, faster and more innovative methods of building can be created. Large complex buildings are already being built with the help of superfast internet connections from companies.

Superfast network speeds mean that engineers can print out large components offsite before transporting them. This removes the need for time-consuming onsite fabrication.

9 Benefits Construction Companies Could Have By using 3D Technology

3D printing is one of the most fascinating technologies to emerge in recent years. 3D printing has already been used to create entire buildings, and, likely, this method will only become more prevalent in the years to come.

There are many benefits that construction companies could get by using additive manufacturing or better known as, “three-dimensional printing.”

Some of these benefits include:

1) Reduced Waste and Improved Accuracy

When creating a physical object through traditional methods, there is often a lot of waste due to the need for excess material. When using additive manufacturing, wasted material is reduced significantly, leading to improved accuracy which leads to better overall results.

This also allows for more complex and intricate designs that would have been impossible in the past with traditional methods.

2. Improved Design Flexibility

With the use of additive manufacturing, designers are given more flexibility to create unique and complex designs that would have been difficult or impossible with traditional methods. This can also help in creating products faster due to fewer design changes which often slow down a project’s development time.

3. Reduced Costs

Additive manufacturing can also lead to significant cost savings for construction companies. This is because less material is wasted, complex designs can be created with ease, and products can be made faster with fewer design changes.

4. Faster Turnaround Times

Another benefit of 3D Printing is that it leads to faster turnaround times for products. This is because traditional methods often require a lot of time to set up, and each step needs to be completed in sequence. With 3D printing, multiple steps can be completed at the same time which leads to faster production times.

5. Improved Quality

The use of additive manufacturing often leads to improved quality in products. This is because there is less waste, and designers have more flexibility to create unique designs.

Additionally, products can be made faster with fewer design changes, which often leads to improved quality overall.

6. Environmental Benefits

Additive manufacturing also leads to reduced carbon emissions by using less energy and raw materials. This is because there are fewer mistakes, which means less material wasted in a project. Additionally, complex designs can be created with ease resulting in further reductions of waste on a project.

Plus, since products can be made faster with fewer design changes, this also leads to less energy being used in the manufacturing process.

7. Better Collaboration

Using additive manufacturing allows for better collaboration between teams since all project members can easily view the design process in real-time. This leads to better communication and more successful projects overall.

Plus, having a digital model of the product that is being produced makes it easier for team members to understand how the final product will look, thus leading to better communication and collaboration.

This allows for a much smoother design process overall, which leads to increased efficiency in projects.

8. Improved Sustainability

One of the most significant benefits of additive manufacturing is improved sustainability. This is because less material is wasted, and products can be made faster with fewer design iterations which often results in better quality overall.

9. Improved Complexity of Products

Additive manufacturing also leads to the creation of more complex designs than traditional methods. This can allow companies to create products with unique and intricate designs which wouldn’t have been possible before.

Plus, there are usually fewer errors overall when using additive manufacturing which results in better quality on projects overall.

Conclusion

The future of construction is brighter with 3D printing. If you’re on the fence about whether or not to invest in a new construction project, then consider that 3D printing may be able to help you turn your idea into reality without any hassle at all.

With this technology, it will become easier than ever before for people who are interested in their own home design and architecture projects to get started quickly by turning mere sketches into tangible models within minutes instead of days.